Description

Horizontal Pulsating Vacuum Autoclave

Pulsating vacuum Sterilizer with the features of PLC and HMI automatic program control, automatic temperature recording and printing, etc. It is suitable for hospitals, pharmaceutical factories, food industries, scientific research institutes and other units to sterilize and dry clothing, dressings, metal instruments, culture medium.etc.

Structure And Performance Features

The sterilizer is mainly consisted of main body, door, pipeline system, control system, and decorative board and so on.

- Main body

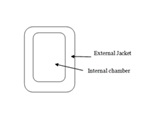

The chamber is rectangle and made of AISI304, is checked by X ray. Its design pressure is 0.245Mpa. Every equipment

attaches quality specification materials signed by labor ministry, which are suitable for the configuration and requirements of Steel Pressure Vessel

According to mechanical and chemical treatment, the chamber surface is bright, beautiful and corrosion resistant.

- Insulating layer

The insulating layer is made by aluminum silicate which is the best insulating material.

- Decorative board

The equipment is rectangular, having stainless steel decorating cover.

- Seal door

The equipment adopts single door.

National patent sealing technology – closed inflatable seal ring with compressed air.

Automatic Control lockout switch, senses when door closed and tight, and mechanical safety interlock device

- Pipe system

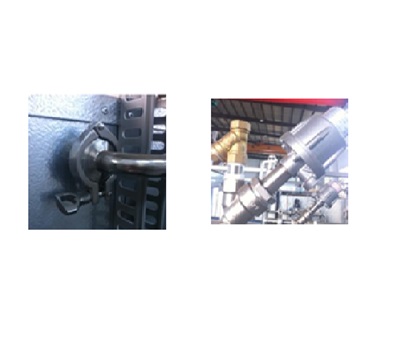

- The pipes for inner pure steam and air filling are made of AISI 304 with the international advanced principle ‘long running water, long flowing gas’ that make sure the energy clean. Calorie-hoop inter linkage fast joint not only solve the resorted of the convention threaded fittings, but also convenient for dismount and part changing, cleaning.

- The filters for pure steam pipe, air filling pipe and vacuum pipe, the performance is excellent with no medium break or contamination unload. That can be repeated clean and repeated flush.

- Control valves. The pneumatic water proof hammer angle valve is fixed in cooling water system that the system can work more

- smoothly. Other valves are heat resistance angle pneumatic valve which are special for steam (180℃). They are bid directional

- self-adjustable airproof, big flux with 6 million times working life

- Control system

It is integrated by Siemens PLC + HMI + Data logger + Printer, this system is easy to implement the program selection, parameter setting, equipment operation, report processing, printing, storing and others functions.

The F0 value and the temperature time gives double guarantee for sterilization. Built in USB port. At the same time, equip with independent temperature monitoring system.

- Vacuum system

Water-ring vacuum pump: Quiet, high vacuum rate. The steam condenser is fitted in the exhaust/vacuum line to condense the steam before entering inside the vacuum pump.

- Safety System

² Mechanical pressure relief safety valve for chamber and jacket

² Over-pressure protective device

² Over-temperature protective device

² Protective measure device of door safety

² Interlock function device of door

² Perfect fault information warning and fault self-diagnosis function

- GMP

The GMP confirmation access is fixed which is convenient to do the confirmation. The GMP validation ports of 16 temperature sensor are used for validation

- Loading system

Including the Special designed loading tray.

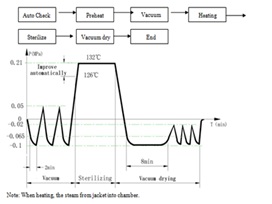

III.Process Flow

Automatic control: